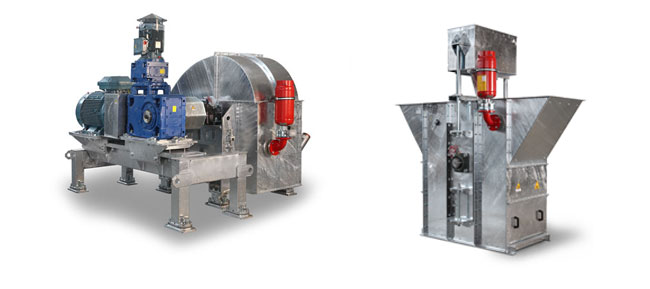

The CE Mark (fig. 1) means that the machine must comply to all the applicable European directives in force at the time of its commercialization. In particular, this machine must responds to the Directive 2006/42/EC, known as the new machinery directive.Michael Kors Handbags Outlet To meet this directive, each type of machine must bear a complete technical dossier of risk assessment.

The Annex 1 of the Machinery Directive in the section 1.5.7 reads: "The machine must be designed and constructed to avoid any risk of explosion posed by the machine itself or by gases, liquids, dusts, vapors or other substances produced or used from the machine. The machine must be, as regards the risk of explosion due to its use in potentially explosive atmospheres, conformed to EU directives." To obtain the CE mark the machine under investigation, in our case the bucket elevator, must avoid an explosion caused by the same or by substances used in it regardless of the external environment. The rule also says that, when installed in an explosive atmosphere, the machine must also be compliant with ATEX (ATmosphères EXplosibles) EU Directive and bear the corresponding ATEX mark according to the classification of the area in which it will be installed (fig. 2).

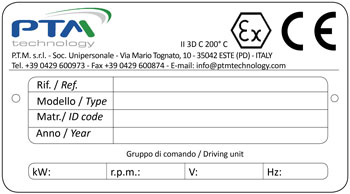

In the substance, with respect to the internal construction, there is no difference between the machine with ATEX mark and the machine with CE only mark if the machine is constructed for transporting powders which can form a potentially explosive atmosphere in its interior: coach outlet in the risk assessment for the CE mark it is mandatory to consider the formation of potentially explosive atmosphere inside the machine. Although the ATEX Directive is not applicable to the risks of explosion generated inside the elevator, you have to install equipment which complies with the requirements in the areas of the same machine where there is a risk of accumulation of potentially explosive atmosphere and use the harmonized standards, including EN 1127 (which lists all the possible sources of ignition that may occur) for the risk analysis. According to the characteristics of the product, mainly the MIE (Minimum Ignition Energy) and the MIT (Minimum Ignition Temperature) the construction must avoid the possibility of achieving certain temperatures, or developing electrostatic sparks and flames; in the case of products with particularly easy ignition also mechanical sparks or electrostatic plume discharge sources are to be evaluated in the construction of the bucket elevator. For these above mentioned reasons, all the elevators for the transport of organic products that are put on the market in the EU, for the mere fact of bearing the CE mark, should be provided with anti-slipping and anti-skidding equipment (fig. 3) to prevent rubbing and consequent heating of the belt and also must guarantee electrical continuity in all its parts and be grounded.

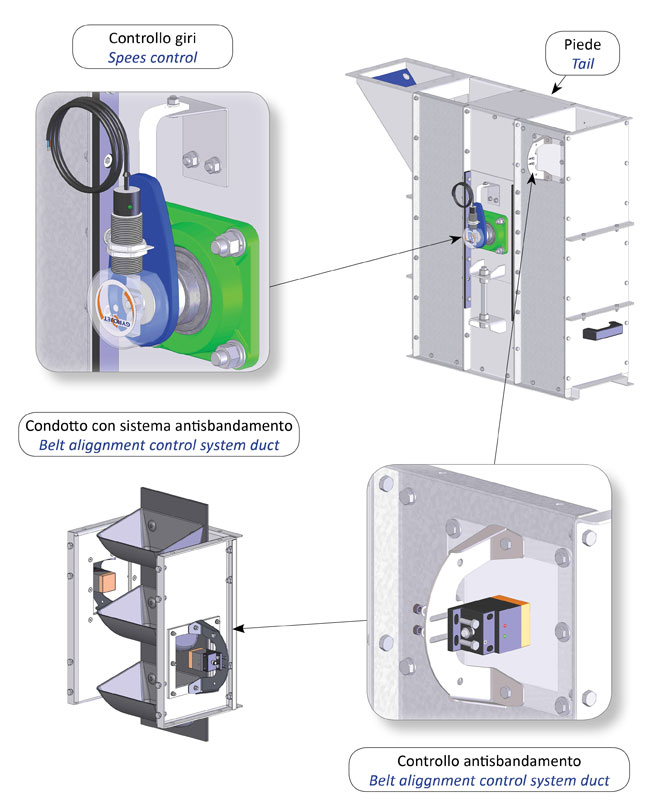

When these systems are not sufficient to avoid the risk of explosion, mainly because of the product handled, it will be necessary to ensure the confinement of the explosion with venting or its suppression (fig. 4). In the supply of such machines is extremely important to define the range of use as specified in the instructions for the preparation of technical documentation.