The EU Directive 1999/92/CE, that was adopted in Italy with National Law No. 81/1008,high quality replica watches deals with the risk assessment based on the potentially explosive atmospheres. These can consist of substances mixed with air, like gas or dusts.

Areas are classified into a number of risk assessment zones depending on the likelihood of mixtures to spread and to form explosive atmospheres.

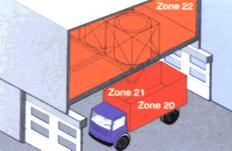

Zones 2,1 and 3 are relevant for gases, as zones 22, 21 and 20 are for dusts. The ranking given to these zones depends on the likelihood of an explosive atmosphere to occur and of its persistence if it does.

Let’s have a look at the dust zones:

ZONE 20: It describes an area in which an explosive atmosphere in the form of combustible dust in the air is permanent or persisting for long periods.

Example: Such conditions are often the case inside containers, ducts, equipments, etc. It is typically referred to the interior of plants (mills, dryers, mixers, ducts for material handling, bins, etc) whenever it is very likely that explosive mixtures may be generated out of considerable quantities of dangerous dusts and they persist forever, for a long time, or take place quite often.

ZONE 21: It describes an area in which during normal operations an explosive mixture in the form of dusts in the air is likely to occur.

Example: This category can include areas in the vicinity of sampling or collection sites where dusts are stored. In this case during normal operation a mixture of highly explosive inflammable dusts and air may be created.

Zone 22. It describes an area where during normal operation, an explosive atmosphere generated by dust is not likely to occur, and if it does, it will persist only for a short time.

Example: It may include areas in which leakage of dusts from inside the plant is likely to occur and create large heaps of dangerous dusts.

In a previous article on technical solutions we explained that the zone defines the mandatory protection measures, i.e. in the Zone 22 no ignition sources are allowed during normal operations; in the zone 21, in addition to this the ban is also in place during predictable malfunctions,in the zone 20 during extraordinary malfunctions or in the event of two malfunctions happening at the same time.

The zones define the category of equipments manufactured after the directive coming into force that are intended for use in that particular area.

Zone 22 requires category 3D marked equipment, zone 21 requires category 2D marked equipment and zone 20 requires category 1D marked equipment. Appropriate ATEX posters with markings are mandatory.